Contact Us

E-mail :

info@delinco.com, sales@delinco.com

WhatsApp:

+86-13930129172

Address:

271 Yuanshi Street, Shijiazhuang City, Hebei Province, China

Slurry Pump Parts

Description: Impeller is one of the important parts of slurry pump Centrifugal pump needs impeller to generate centrifugal force to transport slurry Centrifugal force is produced by the impeller rotating to a certain speed

Sheath because the shape resembles a snail, also known as volute.

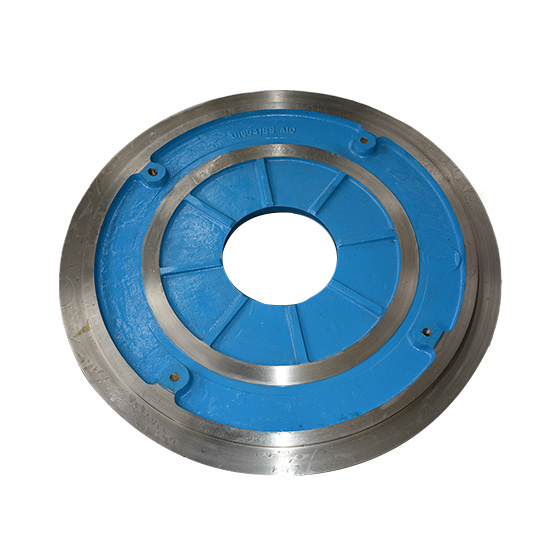

The slurry pump front guard plate is one of the flow parts of the slurry pump, because the transported materials contain various solid particles and acid and alkali ions, which cause serious wear and corrosion to the flow parts of the slurry pump, so the slurry pump front guard plate and other flow parts have higher wear resistance and corrosion resistance requirements. At present, the material of the slurry pump front protection plate is generally wear-resistant alloy, rubber, ceramics, polyurethane. Among them, the alloy has high hardness and good wear resistance, but poor corrosion resistance. Ceramic hardness, wear resistance, corrosion resistance, but brittle, difficult to be used in slurry pump.

The rear guard plate of slurry pump is one of the flow parts of slurry pump. Because the transported material contains various solid particles and acid and alkali ions, it causes serious wear and corrosion to the flow parts of slurry pump, so the rear guard plate and other flow parts of slurry pump have higher wear resistance and corrosion resistance requirements. The material of the rear protection plate of the slurry pump after the eye is generally wear-resistant alloy, rubber, ceramics, polyurethane. Among them, the alloy has high hardness and good wear resistance, but poor corrosion resistance. Ceramic hardness, wear resistance, corrosion resistance, but brittle, difficult to be used in slurry pump.

The axially split pump housing is used for pressure.

The seal of auxiliary impeller of slurry pump is sealed by hydrodynamic action, which belongs to non-contact seal. Air or water produces pressure under the rotating action of the auxiliary impeller, and forms a balance of air or water slurry with the slurry on the outer edge of the auxiliary impeller, thus resisting the external leakage of the liquid at the outlet of the main impeller.

The vacuum cover of the slurry pump and the packing box belong to different forms of shaft seals.

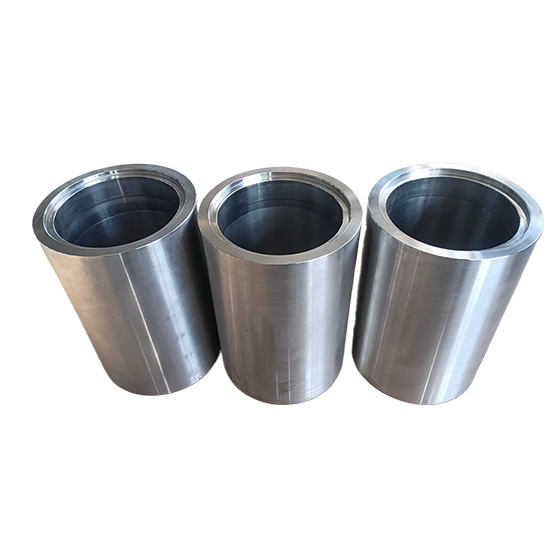

Various options available from standard to hardened sleeves with O-Ring seals at both ends protects the shaft.

The shaft of the centrifugal pump is the main part of the rotor, the shaft is equipped with impeller, sleeve and other parts, with the support of the bearing in the pump body for high-speed rotation, to transfer torque and support the impeller to maintain the normal operation of the working level, is the key part of the operation, in the centrifugal pump as a whole is very critical. The shaft often uses 45# carbon steel and 40Cr alloy steel, as well as 42CrMo, 40CrNiMoA alloy steel, 2205/2507 duplex stainless steel and other different materials.