Material selection method for chemical pumps

Nov 29,2022

As one of the strong corrosive media, sulphuric acid is an important industrial raw material for a wide range of uses. For concentrations above 80% and temperatures less than 80 °C, carbon steel and cast iron have good corrosion resistance, but it is not suitable for use as a material for pumps and valves

, sulfuric acid as one of the strong corrosive medium, Sulfuric acid is a very wide range of important industrial raw materials. Different concentrations and temperatures of sulfuric acid on the material corrosion differences, for concentrations above 80%, the temperature is less than 80 ℃ of concentrated sulfuric acid, carbon steel and cast iron have better corrosion resistance, but it is not suitable for high-speed flow of sulfuric acid, Not suitable for use as a pump valve material; ordinary stainless steel such as 304 (0Cr18Ni9), 316 (0Cr18Ni12Mo2Ti) for sulfuric acid media is also limited use. Therefore, pump valves for conveying sulphuric acid is usually made of high silicon cast iron (difficult to cast and process) and high alloy stainless steel (No. 20 alloy). Fluorine plastic has better resistance to sulphuric acid, using fluorine lined pumps (F46) is a more economic choice.

, Hydrochloride acid Decidedly most metal materials are not resistant to hydrogen acid corrosion (including a variety of stainless steel materials), containing molybdenum high silicon with iron can only be used for 50 ℃, 30% of the following hydrological acid. In contrast to metal materials, most non-metallic materials have good corrosion resistance to hydrochloride acid, so rubber-lined pumps and plastic pumps (such as polypropylene, fluorine plastic, etc.) is a good choice for conveying hydrochloric acid.

, nitric acid Most of the general metal in nitric acid is rapidly corroded and destroyed, stainless steel is the most widely used nitric acid resistant materials, all concentrations of nitric acid at room temperature have good corrosion resistance, it is worth mentioning that the molybdenum-containing stainless steel (such as 316, 316L) On nitric acid corrosion resistance is not only not better than ordinary stainless steel (such as 304, 321), submitted even worse. For high temperature nitric acid, titanium and titanium alloy materials are usually used.

, acetic acid It is one of the most corrosive substances in organic acids, ordinary steel in all concentrations and temperatures of acetic acid will be seriously corrosive, stainless steel is excellent acetic acid resistant materials, containing molybdenum 316 stainless steel can also be applied to high temperature am acid For high temperature and highly concentrated acetic acid or containing other corrosive media and other demanding requirements, high alloy stainless steel pumps or fluorine plastic pumps can be used.

5, Alkali (sodium hydrogen) Steel is widely used in the following 80 ℃, 30% concentration within the sodium hydrogen solution, there are many factors at 100 ℃, 75% below when using ordinary steel, although corrosion increased, but the economy is good. Ordinary stainless steel corrosion resistance of lye compared with cast iron has no obvious advantages, as long as the medium allows a small amount of iron adoxture is not recommended to use stainless steel. For high temperature lay more titanium and titanium alloy or high alloy stainless steel.

, Ammonia (Ammonia Hydroxide) Most metals and non-metals in liquid ammonia and ammonia (Ammonia Hydroxide) corrosion are very light, only copper and copper alloy should not be used.

, salt water (seawater) ordinary steel in sodium chloride solution and seawater, salt water corrosion rate is not too high, generally must be protected by coatings; all types of stainless steel also has a very low uniform corrosion rate, but may be caused by choride ions and located corrosion, Usual using 316 stainless steel is better.

, alcohols, ketones, esters, ethers Common alcohol media are methanol, ethanol, ethylene glycol, propanol, etc., ketone media are acetone, butanone, etc., ester media are a variety of methyl ester, ethyl ester, etc., ether media are methyl ether, ether, Etc., They are basic not corrosive, commonly used materials can be applied, the specific choice should also be based on the properties of the medium and related requirements to make a reasonable choice. It is also worth noting that ketones, esters and ethers are soluble in a variety of rubber, so avid mistakes when picking up sealing materials.

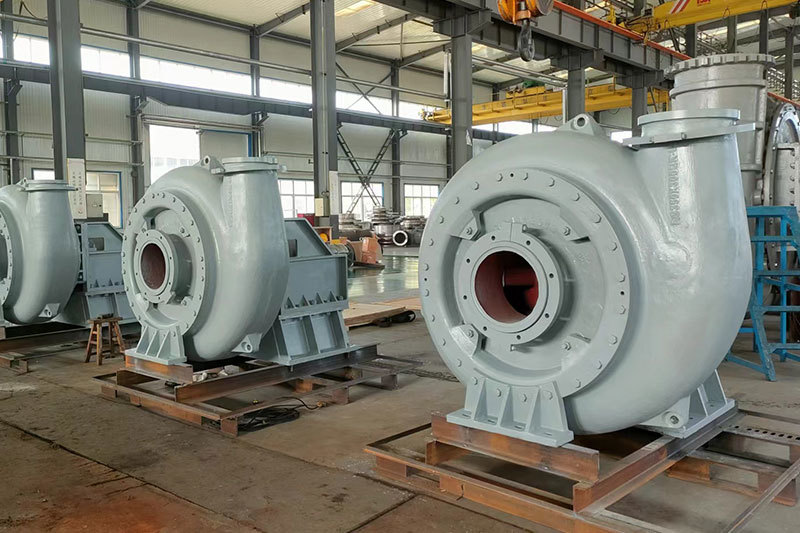

Chemical pumps

PREVIOUS:

Contact Us

E-mail :

info@delinco.com, sales@delinco.com

WhatsApp:

+86-13930129172

Address:

271 Yuanshi Street, Shijiazhuang City, Hebei Province, China