Contact Us

E-mail :

info@delinco.com, sales@delinco.com

WhatsApp:

+86-13930129172

Address:

271 Yuanshi Street, Shijiazhuang City, Hebei Province, China

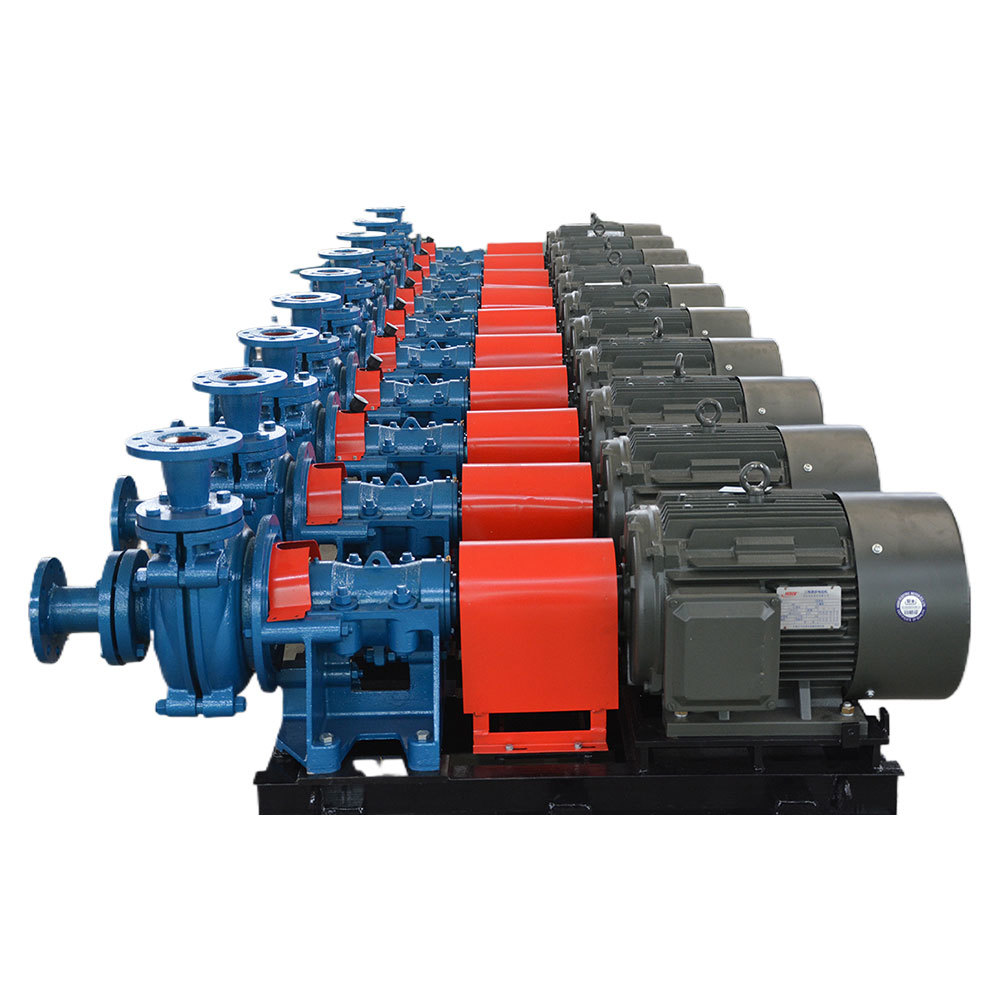

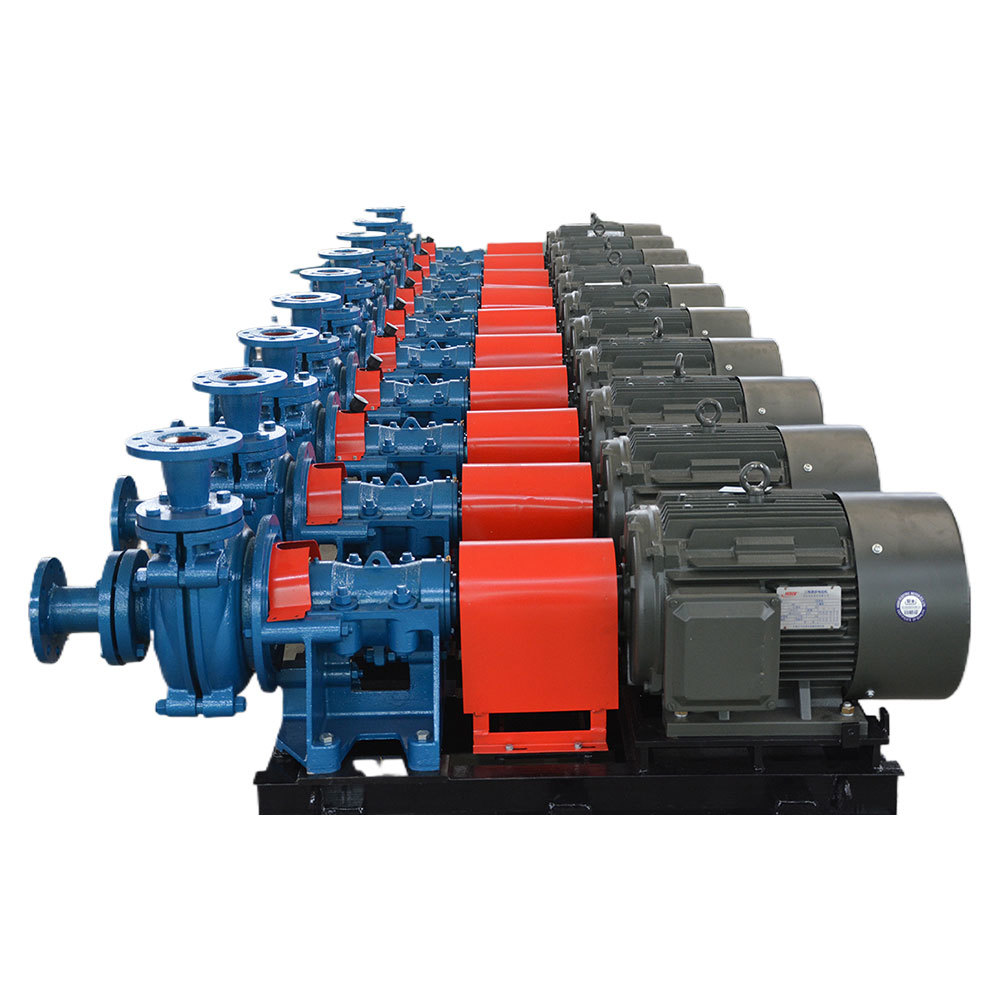

DH Slurry Pump

1. Double pump casing structure, efficient, wear-resistant, and stable performance

2. The parts have strong interchangeability, and the lining and impeller materials can be made of wear-resistant metals.

3. The pump outlet direction can be rotated at 45 ° intervals for installation and use at eight different angles.

4. It can be connected in series at multiple levels, and can be driven by belt or direct connection.

5. The shaft seal can use packing seal, auxiliary impeller seal, or mechanical seal.

6. The rotation direction of the pump is clockwise when viewed from the drive end.

隐藏域元素占位

40X25DH-B

40X25DHR-B

40X25DHH-C

50X40DH-B

50X40DHR-B

70X50DH-C

70X50DHR-C

70X50DHH-D

100X75DH-C

100X75DHR-C

100X75DHH-E

150X100DH-D

150X100DHR-D

150X100DHH-S

200X150DH-R

200X150DHR-R

250X200DH-E

250X200DH-ST

250X200DHR-ST

300X250DH-ST

300X250DHR-ST

350X300DH-ST

350X300DHR-ST

400X350DH-TU

500X400DH-TU

Model

40X25DH-B

Capacity

12.6-26.8 m³/h

Head(TDH)

6-68 m

Allowable Max. Power

15 kW

Speed

1200-3800 r/min

NPSH

2-4 m

Max. Efficiency

40%

Model

40X25DHR-B

Capacity

10.8-25.2 m³/h

Head(TDH)

7-52 m

Allowable Max. Power

15 kW

Speed

1400-3400 r/min

NPSH

2-4 m

Max. Efficiency

35%

Model

40X25DHH-C

Capacity

16.2-34.2 m³/h

Head(TDH)

25-92 m

Allowable Max. Power

30 kW

Speed

1400-2200 r/min

NPSH

2-5.5 m

Max. Efficiency

20%

Model

50X40DH-B

Capacity

32.4-72 m³/h

Head(TDH)

6-58 m

Allowable Max. Power

15 kW

Speed

1200-3200 r/min

NPSH

3.5-8 m

Max. Efficiency

45%

Model

50X40DHR-B

Capacity

25.2-54 m³/h

Head(TDH)

5.5-41 m

Allowable Max. Power

15 kW

Speed

1000-2600 r/min

NPSH

2.5-5 m

Max. Efficiency

50%

Model

70X50DH-C

Capacity

39.6-86.4 m³/h

Head(TDH)

12-64 m

Allowable Max. Power

30 kW

Speed

1300-2700 r/min

NPSH

4-6 m

Max. Efficiency

55%

Model

70X50DHR-C

Capacity

36-75.6 m³/h

Head(TDH)

13-46 m

Allowable Max. Power

30 kW

Speed

1300-2300 r/min

NPSH

2-4 m

Max. Efficiency

60%

Model

70X50DHH-D

Capacity

68.4-136.8 m³/h

Head(TDH)

25-87 m

Allowable Max. Power

60 kW

Speed

850-1400 r/min

NPSH

3-7.5 m

Max. Efficiency

47%

Model

100X75DH-C

Capacity

86.4-198 m³/h

Head(TDH)

9-52 m

Allowable Max. Power

30 kW

Speed

1000-2200 r/min

NPSH

4-6 m

Max. Efficiency

71%

Model

100X75DHR-C

Capacity

79.2-180 m³/h

Head(TDH)

5-34.5 m

Allowable Max. Power

30 kW

Speed

800-1800 r/min

NPSH

3-5 m

Max. Efficiency

59%

Model

100X75DHH-E

Capacity

126-252 m³/h

Head(TDH)

12-97 m

Allowable Max. Power

120 kW

Speed

600-1400 r/min

NPSH

2-5 m

Max. Efficiency

50%

Model

150X100DH-D

Capacity

162-360 m³/h

Head(TDH)

12-56 m

Allowable Max. Power

60 kW

Speed

800-1550 r/min

NPSH

5-8 m

Max. Efficiency

65%

Model

150X100DHR-D

Capacity

144-324 m³/h

Head(TDH)

12-45 m

Allowable Max. Power

60 kW

Speed

800-1350 r/min

NPSH

3-5 m

Max. Efficiency

65%

Model

150X100DHH-S

Capacity

324-720 m³/h

Head(TDH)

30-118 m

Allowable Max. Power

560 kW

Speed

600-1000 r/min

NPSH

3-8 m

Max. Efficiency

64%

Model

200X150DH-R

Capacity

360-828 m³/h

Head(TDH)

10-61 m

Allowable Max. Power

300 kW

Speed

500-1140 r/min

NPSH

2-9 m

Max. Efficiency

72%

Model

200X150DHR-R

Capacity

324-720 m³/h

Head(TDH)

7-49 m

Allowable Max. Power

300 kW

Speed

400-1000 r/min

NPSH

5-10 m

Max. Efficiency

65%

Model

250X200DH-E

Capacity

666-1440 m³/h

Head(TDH)

14-60 m

Allowable Max. Power

120 kW

Speed

600-1100 r/min

NPSH

4-10 m

Max. Efficiency

73%

Model

250X200DH-ST

Capacity

612-1368 m³/h

Head(TDH)

11-61 m

Allowable Max. Power

560 kW

Speed

400-850 r/min

NPSH

4-10 m

Max. Efficiency

71%

Model

250X200DHR-ST

Capacity

540-1188 m³/h

Head(TDH)

12-50 m

Allowable Max. Power

560 kW

Speed

400-750 r/min

NPSH

4-12 m

Max. Efficiency

75%

Model

300X250DH-ST

Capacity

936-1980 m³/h

Head(TDH)

7-68 m

Allowable Max. Power

560 kW

Speed

300-800 r/min

NPSH

6 m

Max. Efficiency

82%

Model

300X250DHR-ST

Capacity

720-1620 m³/h

Head(TDH)

7-45 m

Allowable Max. Power

560 kW

Speed

300-650 r/min

NPSH

2.5-7.5 m

Max. Efficiency

80%

Model

350X300DH-ST

Capacity

1260-2722 m³/h

Head(TDH)

13-63 m

Allowable Max. Power

560 kW

Speed

300-600 r/min

NPSH

3-10 m

Max. Efficiency

77%

Model

350X300DHR-ST

Capacity

1152-2520 m³/h

Head(TDH)

13-44 m

Allowable Max. Power

560 kW

Speed

300-500 r/min

NPSH

3-8 m

Max. Efficiency

79%

Model

400X350DH-TU

Capacity

1368-3060 m³/h

Head(TDH)

11-63 m

Allowable Max. Power

1200 kW

Speed

250-550 r/min

NPSH

4-10 m

Max. Efficiency

79%

Model

500X400DH-TU

Capacity

2520-5400 m³/h

Head(TDH)

13-57 m

Allowable Max. Power

1200 kW

Speed

200-400 r/min

NPSH

5-10 m

Max. Efficiency

85%

★ Iron ore beneficiation plant

★ Copper beneficiation plant

★ Gold ore beneficiation plant

★ Molybdenum beneficiation plant

★ Potassium fertilizer plant

★ Other mineral processing plants

★ Aluminum oxide industry

★ Coal washing plant

★ Power plant

★ Sand excavation

★ Building materials industry

★ Chemical Industry

★ Other industries

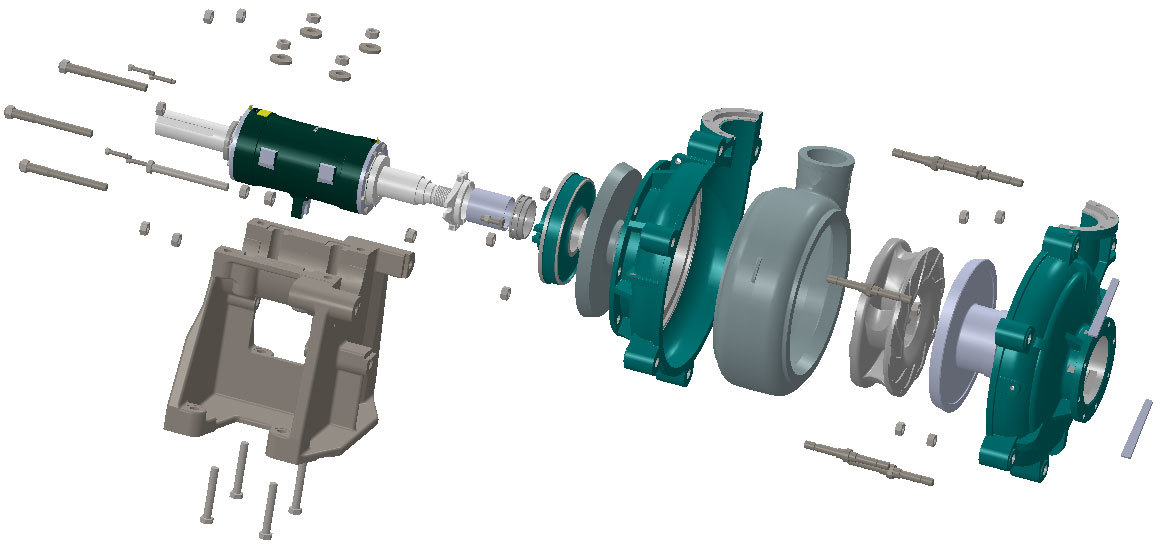

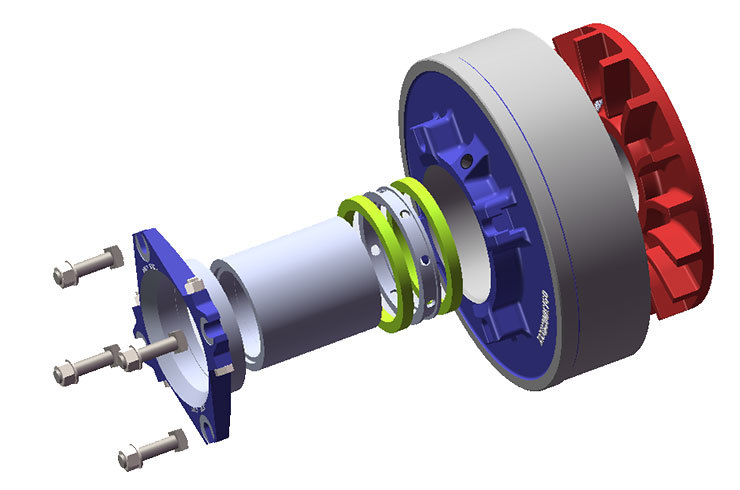

DH slurry pump structure

DH 3D Structure

The axially split pump casing is used for pressure bearing and the inner lining is wear-resistant. The metal inner lining has a certain taper in the matching section to ensure accurate alignment during assembly and to ensure that the parts are easy to disassemble or replace. The cast impeller thread is more suitable for slurry pump conditions, and the back blade reduces the sealing pressure and can minimize backflow.

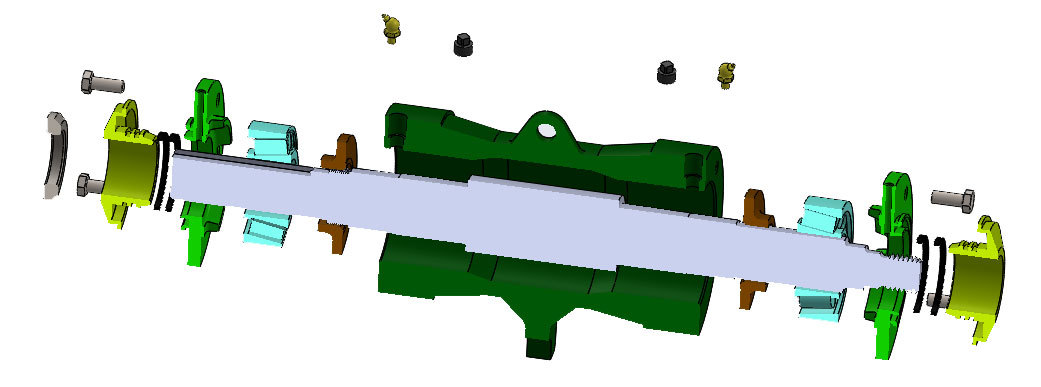

Bearing Assembly

The pump shaft has a large diameter and a heavy-duty cylindrical structure, which is small in size and occupies a small area. Grease lubrication is adopted, so there is no risk of oil leakage, the maintenance is minimal, the rotor is easy to adjust, and it can be used in series.

|

|

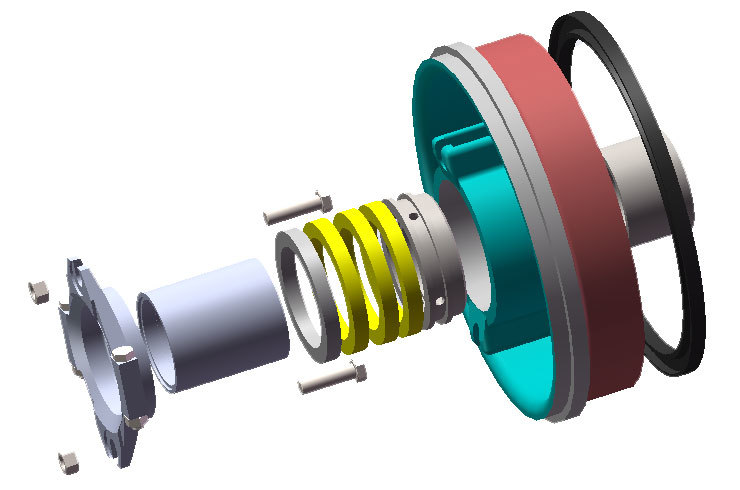

| Packing Seal | Expeller Seal |

Packing seal: conventional shaft seal, suitable for various working conditions, can be equipped with special materials such as polytetrafluoroethylene packing, graphite packing, etc., for corrosive or high temperature conditions. Can be equipped with spray-welded ceramic sleeve, suitable for strong abrasive conditions.

Auxiliary impeller dynamic seal: use the pressure seal generated by the impeller and the auxiliary impeller in series, and the packing or lip seal ring is used as the parking seal.

Mechanical seal: internationally leading sealing technology, leak-free sealing effect. Containerized structure, easy installation and replacement, different structural forms are suitable for different working conditions. The friction pair material is made of high-hardness ceramic and alloy materials. The design and matching of mechanical seal and sealing box conform to the flow state of the medium, so it has high wear resistance and shock resistance, and can ensure customer satisfaction under various harsh working conditions.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products