Contact Us

E-mail :

info@delinco.com, sales@delinco.com

WhatsApp:

+86-13930129172

Address:

271 Yuanshi Street, Shijiazhuang City, Hebei Province, China

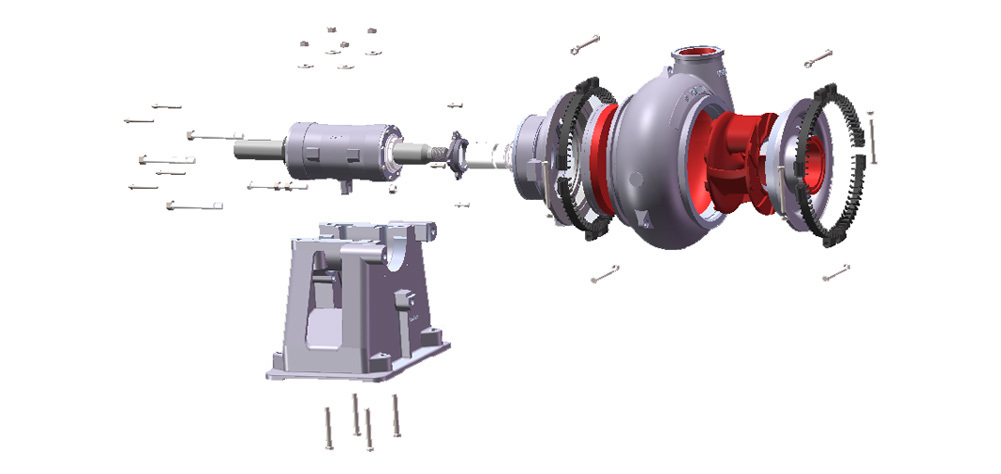

DG Slurry Pump

1. This series of pumps is a single-stage single-suction cantilever horizontal structure, according to the size of the dredging pump structure is divided into two structures: single pump shell and double pump shell.

2. According to the transmission mode, it can be divided into two typical structures: built-in bracket type and pump box type (that is, gear box and pump are integrated).

3. There are two types of built-in bracket lubrication: grease lubrication or thin oil lubrication transmission can be directly connected or belt drive.

隐藏域元素占位

DG250X200L

DG250X200MS

DG300X250L

DG350X300L

DG350X250M

DG450X300M

DG450X350M

DG500X450L

DG600X450MS

DG650X550L

DG650X500MS

DG700X600MS

DG760X700MS

DG800X700L

DG800X750MS

DG900X800L

DG900X850MS

DG1000X900MS

DG1050X950L

DG1200X1000MS

Model

DG250X200L

Capacity

340-870 m³/h

Head(TDH)

10-45 m

Allowable Max. Power

-

Speed

900 r/min

NPSH

<4 m

Max. Efficiency

65-70 %

Model

DG250X200MS

Capacity

520-1000 m³/h

Head(TDH)

38-65 m

Allowable Max. Power

-

Speed

850 r/min

NPSH

<4 m

Max. Efficiency

70-74 %

Model

DG300X250L

Capacity

500-950 m³/h

Head(TDH)

10-42 m

Allowable Max. Power

-

Speed

700 r/min

NPSH

<4 m

Max. Efficiency

65-68 %

Model

DG350X300L

Capacity

700-2400 m³/h

Head(TDH)

10-38 m

Allowable Max. Power

-

Speed

650 r/min

NPSH

<4 m

Max. Efficiency

74-78 %

Model

DG350X250M

Capacity

500-1500 m³/h

Head(TDH)

35-68 m

Allowable Max. Power

-

Speed

600 r/min

NPSH

<4 m

Max. Efficiency

74-78 %

Model

DG450X300M

Capacity

900-2500 m³/h

Head(TDH)

40-70 m

Allowable Max. Power

-

Speed

550 r/min

NPSH

<4 m

Max. Efficiency

76-80 %

Model

DG450X350M

Capacity

1200-3500 m³/h

Head(TDH)

40-70 m

Allowable Max. Power

-

Speed

550 r/min

NPSH

<4 m

Max. Efficiency

71-75 %

Model

DG500X450L

Capacity

1200-3800 m³/h

Head(TDH)

10-43 m

Allowable Max. Power

-

Speed

48 r/min

NPSH

<4 m

Max. Efficiency

78-80 %

Model

DG600X450MS

Capacity

1500-4200 m³/h

Head(TDH)

40-76 m

Allowable Max. Power

-

Speed

500 r/min

NPSH

<4 m

Max. Efficiency

80 %

Model

DG650X550L

Capacity

1800-5500 m³/h

Head(TDH)

10-48 m

Allowable Max. Power

-

Speed

420 r/min

NPSH

<4 m

Max. Efficiency

83 %

Model

DG650X500MS

Capacity

2000-6000 m³/h

Head(TDH)

35-73 m

Allowable Max. Power

-

Speed

440 r/min

NPSH

<4 m

Max. Efficiency

85 %

Model

DG700X600MS

Capacity

2500-8000 m³/h

Head(TDH)

30-76 m

Allowable Max. Power

-

Speed

470 r/min

NPSH

<4 m

Max. Efficiency

85 %

Model

DG760X700MS

Capacity

2800-10000 m³/h

Head(TDH)

30-76 m

Allowable Max. Power

-

Speed

380 r/min

NPSH

<4 m

Max. Efficiency

81 %

Model

DG800X700L

Capacity

3000-8500 m³/h

Head(TDH)

10-43 m

Allowable Max. Power

-

Speed

380 r/min

NPSH

<4 m

Max. Efficiency

81 %

Model

DG800X750MS

Capacity

5500-14000 m³/h

Head(TDH)

34-74 m

Allowable Max. Power

-

Speed

349 r/min

NPSH

<4 m

Max. Efficiency

81 %

Model

DG900X800L

Capacity

4000-13000 m³/h

Head(TDH)

10-40 m

Allowable Max. Power

-

Speed

280 r/min

NPSH

<4 m

Max. Efficiency

85 %

Model

DG900X850MS

Capacity

7000-17000 m³/h

Head(TDH)

34-74 m

Allowable Max. Power

-

Speed

330 r/min

NPSH

<4 m

Max. Efficiency

85 %

Model

DG1000X900MS

Capacity

8000-20000 m³/h

Head(TDH)

34-74 m

Allowable Max. Power

-

Speed

175 r/min

NPSH

<4 m

Max. Efficiency

85 %

Model

DG1050X950L

Capacity

7500-17000 m³/h

Head(TDH)

10-38 m

Allowable Max. Power

-

Speed

258 r/min

NPSH

<4 m

Max. Efficiency

85 %

Model

DG1200X1000MS

Capacity

8000-28000 m³/h

Head(TDH)

24-75 m

Allowable Max. Power

-

Speed

290 r/min

NPSH

<4 m

Max. Efficiency

85-87 %

★ River dredging

★ Reservoir desilting

★ Coastal reclamation

★ Deep sea mining

DG slurry pump structure

DG 3D Structure

DG series gravel pump is single-stage, single-suction, cantilever, horizontal structure. The pump is a single-shell pump. Grease lubrication and thin oil lubrication are used for continuous conveying of highly abrasive materials whose particles are too large to be conveyed by ordinary slurry pumps. Among them, DGH is a high-lift gravel pump. The flow-through parts of the pump are made of hard nickel, high chromium and other wear-resistant materials. The discharge direction of the pump can be at any position of 360°, with the advantages of easy installation and use, good cavitation resistance, and wear resistance. The rotation direction of the pump is clockwise from the drive end

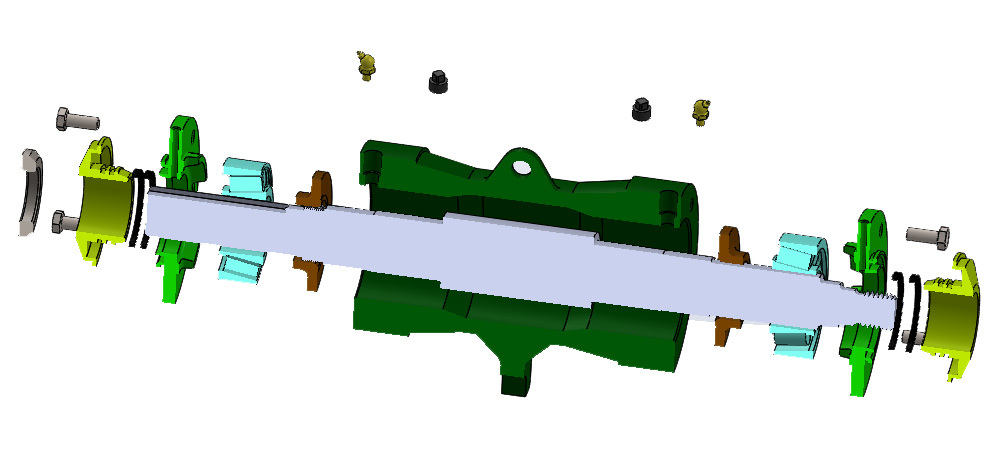

Bearing Assembly

The pump shaft has a large diameter and a heavy-duty cylindrical structure, which is small in size and occupies a small area. Grease lubrication is adopted, so there is no risk of oil leakage, the maintenance is minimal, the rotor is easy to adjust, and it can be used in series.

|

|

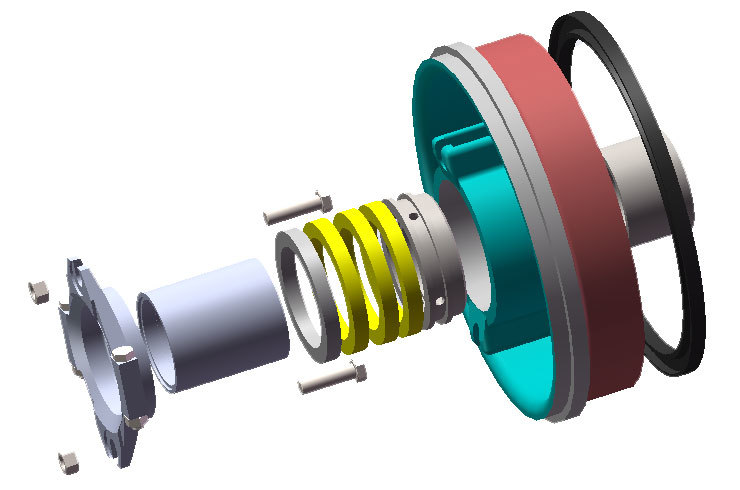

| Packing Seal | Expeller Seal |

Packing seal: conventional shaft seal, suitable for various working conditions, can be equipped with special materials such as polytetrafluoroethylene packing, graphite packing, etc., for corrosive or high temperature conditions. Can be equipped with spray-welded ceramic sleeve, suitable for strong abrasive conditions.

Auxiliary impeller dynamic seal: use the pressure seal generated by the impeller and the auxiliary impeller in series, and the packing or lip seal ring is used as the parking seal.

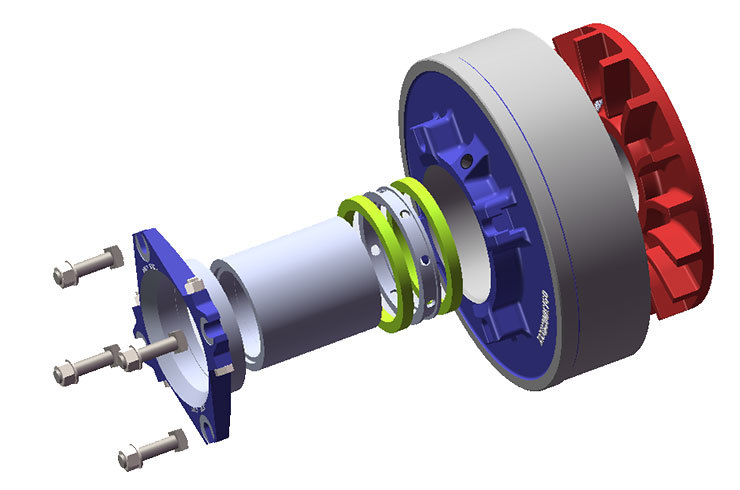

Mechanical seal: internationally leading sealing technology, leak-free sealing effect. Containerized structure, easy installation and replacement, different structural forms are suitable for different working conditions. The friction pair material is made of high-hardness ceramic and alloy materials. The design and matching of mechanical seal and sealing box conform to the flow state of the medium, so it has high wear resistance and shock resistance, and can ensure customer satisfaction under various harsh working conditions.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products