Contact Us

E-mail :

info@delinco.com, sales@delinco.com

WhatsApp:

+86-13930129172

Address:

271 Yuanshi Street, Shijiazhuang City, Hebei Province, China

DH(R) Series Slurry Pump

Suitable for conveying strong abrasion and high concentration slag slurry in industries such as metallurgy, mining, coal, and power, such as raw ore, intermediate ore, concentrate, tailings, etc. in black non-ferrous mines.

Capacity: 7~5000m³/h

Head: 5~59m

Speed (r/min): 1200~3800r/min

- Commodity name: DH(R) Series Slurry Pump

- Description

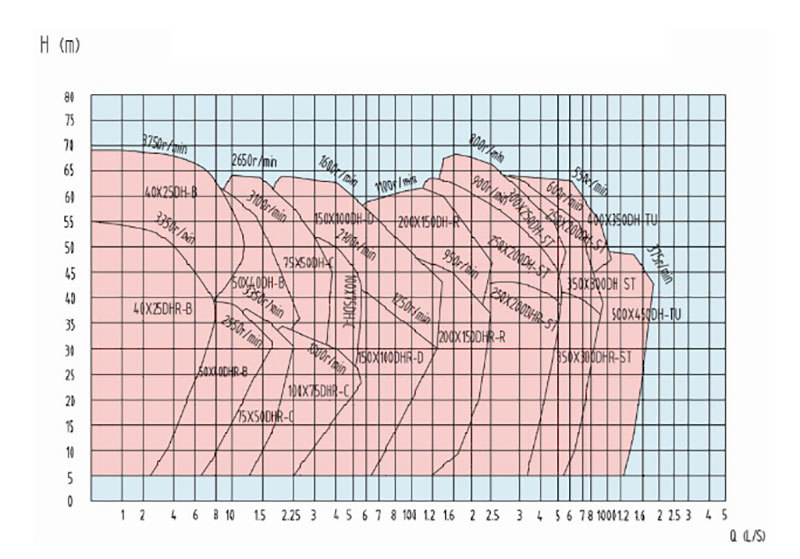

- Selection Chart

- Performance Parameter

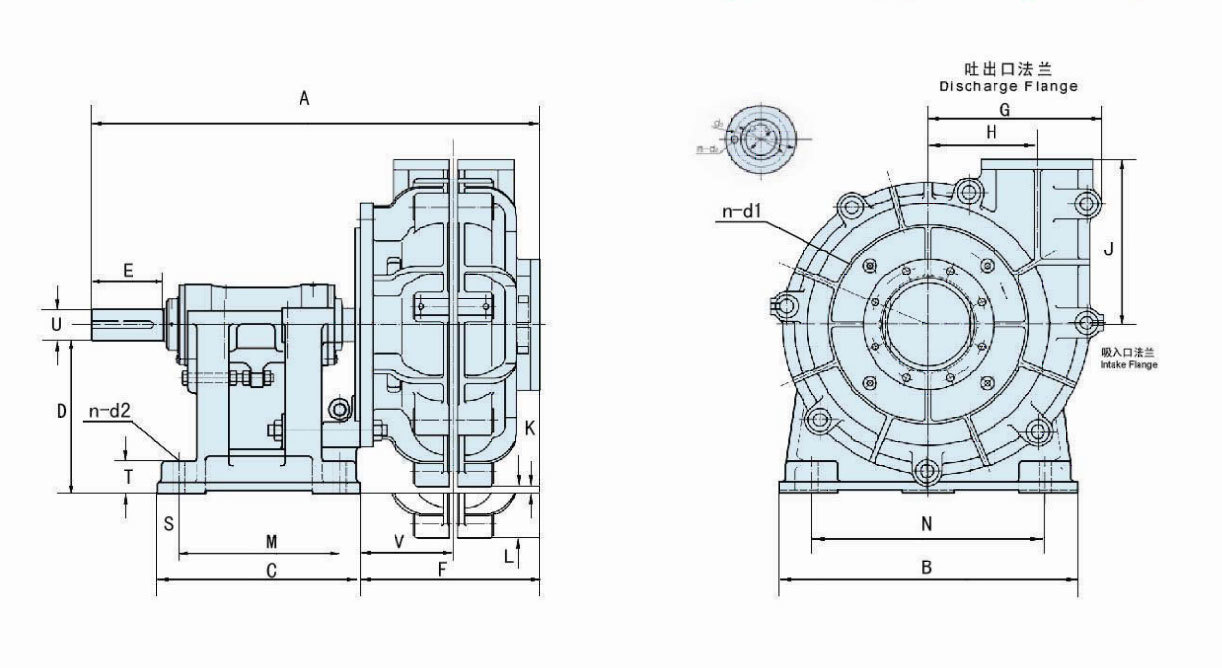

- Installation Dimension

-

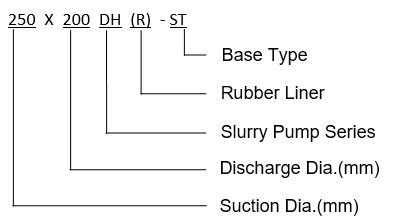

Model Meaning

Characteristic

Capacity: 7~5000m³/h Head: 5~59m Speed (r/min): 1200~3800r/min NPSHr(m) 2~4m Allowable Matting Max.Power(kW): 15~1200kw Material: M/RU Double pump housing structure. Efficient, wear-resistant, stable performance, and strong interchangeability of parts. The lining and impeller materials can be made of wear-resistant metal or rubber. The pump outlet direction can be rotated at eight different angles at 45 ° intervals for installation and use. It can be connected in multiple stages and can be driven by belt or direct transmission. The shaft seal can use packing seal, auxiliary impeller seal, or mechanical seal. The rotation direction of the pump is clockwise when viewed from the drive end.

Application

Suitable for conveying strong abrasion and high concentration slag slurry in industries such as metallurgy, mining, coal, and power, such as raw ore, intermediate ore, concentrate, tailings, etc. in black non-ferrous mines.

The sand slurry pump is a robust and efficient device designed to handle the transportation of abrasive and viscous materials. Equipped with a powerful motor, it is capable of effectively pumping slurry composed of sand, water, and other solids.

-

Section Chart of DH(R) Type Slurry Pump

-

Type Allowable Matting Max.Power(kW) Material Water Clearance Performance Impeller Liner Impeller Capacity(Q) Head(H) Speed(n) Max. Efficiency NPSH Impeller No. Impeller Dia. m³/h l/s m r/min. % m 40X25DH(R)-B 15 M M 12.6-26.8 3.5-8 6-68 1200-3800 40 2--4 5 152 RU RU 10.8-25.2 3-7 7-52 1400-3400 35 2-4 3 152 40X25DHH-C 30 M M 16.2-34.2 4.5-9.5 25-92 1400-2200 20 2-5.5 5 330 50X40DH(R)-B 15 M M 32.4-72 9--20 6-58 1200-3200 45 3.5-8 5 184 RU RU 25.2-54 7--15 5.5-41 1000-2600 50 2.5-5 5 178 70X50DH(R)-C 30 M M 39.6-86.4 11--24 12-64 1300-2700 55 4--6 5 214 RU RU 36-75.6 10--21 13-46 1300-2300 60 2--4 5 213 70X50DHH-D 60 M M 68.4-136.8 19-38 25-87 850-1400 47 3-7.5 5 457 100X75DH(R)-C 30 M M 86.4-198 24-55 9-52 1000-2200 71 4--6 5 245 RU RU 79.2-180 22-50 5-34.5 800-1800 59 3--5 5 245 100X75DHH-E 120 M M 126-252 35-70 12-97 600-1400 50 2--5 5 508 150X100DH(R)-D 60 M M 162-360 40-100 12-56 800-1550 65 5--8 5 365 RU RU 144-324 40-90 12-45 800-1350 65 3--5 5 365 150X100DHH-S 560 M M 324-720 90-200 30-118 600-1000 64 3--8 5 711 200X150DH(R)-R 300 M M 360-828 100-230 10-61 500-1140 72 2--9 5 510 RU RU 324-720 90-200 7-49 400-1000 65 5--10 5 510 250X200DH-E 120 M M 666-1440 185-400 14-60 600-1100 73 4--10 5 549 250X200DH(R-ST) 560 M M 612-1368 170-380 11-61 400-850 71 4--10 5 686 RU RU 540-1188 150-330 12-50 400-750 75 4--12 5 686 300X250DH(R)-ST 560 M M 936-1980 260-550 7-68 300-800 82 6 5 762 RU RU 720-1620 200-450 7-45 300-650 80 2.5-7.5 5 762 350X300DH(R)-ST 560 M M 1260-2722 350-770 13-63 300-600 77 3-10 5 965 RU RU 1152-2520 320-700 13-44 300-500 79 3-8 5 965 400X350DH-TU 1200 M M 1368-3060 380-850 11-63 250-550 79 4-10 5 1067 500X400DH-TU 1200 M M 2520-5400 700-1500 13-57 200-400 85 5-10 5 1370 Note:1. M: wear-resistant alloy material RU: rubber

2. Capacity range recommend: 50% Q’≤Q≤110%Q’ (Q’≈ appropriate to capacity at highest efficiency point)

3. NPSH: appropriate to point Q suggested at highest speed -

Modal A B C D U E F G H J K L M N V T S n-d 40X25DH(R)-B 583 295 248 197 28 79 206 181 98 171 46 ----- 143 254 181 38 24 4-Φ14 40X25DHH-C 759 406 311 254 42 121 306 270 194 254 ---- 11 175 356 252 48 32 4-θ19 50X40DH(R)-B 592 295 428 197 28 79 217 205 114 184 33 ---- 143 254 184 38 24 4-θ14 70X50DH(R)-C 768 406 311 254 42 121 281 238 138 210 71 ---- 175 356 233 48 32 4-θ19 70X50DHH-D 986 492 364 330 65 164 389 384 254 368 ---- 51 213 432 298 64 38 4-θ22 100X75DH(R)-C 843 406 311 254 42 121 354 292 149 262 24 ---- 185 356 270 48 32 4-θ19 100X75DHH-E 1240 622 448 457 80 222 492 492 330 432 ---- ---- 257 546 381 76 54 4-θ29 150X100DH(R)-D 1021 492 364 330 65 164 421 406 229 338 11 ---- 213 432 318 64 38 4-θ22 150X100DH(E)-E 1178 622 448 457 80 222 433 406 229 338 138 ---- 257 546 351 76 54 4-θ29 150X100DHH-S 1668 920 780 450 120 280 296 616 413 546 ---- 134 640 760 353 90 70 4-θ35 200X150DH(R)-E 1302 622 448 457 80 222 557 551 318 460 ---- 62 257 546 402 76 54 4-θ29 200X150DH(R)-R 1360 680 590 350 85 215 ---- 511 318 460 ---- 170 490 560 312 70 50 4-θ28 200X150DHH-T 2275 1150 1040 650 150 350 852 835 584 813 ---- 160 880 900 538 125 80 4-θ48 250X200DH(R)-E 1337 622 448 457 80 222 584 613 384 470 ---- 83 257 546 403 76 54 4-θ29 250X200DH(R)-R 1395 680 590 350 85 215 ---- 613 384 470 ---- 190 490 560 314 70 50 4-θ28 250X200DH(R)-ST 1748 1150 780 650 120 280 692 673 419 635 27 ---- 620 900 439 125 80 4-θ48 300X250DH(R)-ST 1816 1150 780 650 120 280 762 775 464 674 ---- 65 620 900 461 125 80 4-θ48 350X300DH(R)-ST 1873 1150 780 650 120 280 812 937 629 832 ---- 224 620 900 486 125 80 4-θ48 400X350DH-ST 2320 1460 1050 900 150 350 953 1048 660 889 ---- 84 860 1200 597 150 95 4-θ79 500X400DH-TU 2475 1460 1050 900 150 350 1100 1420 940 1230 ---- 420 860 1200 615 150 95 4-θ79 Inlet Flange Dimension Outlet Flange Dimension Weight Model D0 D1 D2 N-D1 d0 d1 d2 n-d2 Metal Rubber 40X25DH(R)-B 152 38 114 4-θ16 165 25 127 4-θ16 91 77 40X25DHH-C 152 38 114 4-θ17 152 25 114 4-θ17 318 ---- 50X40DH(R)-B 184 51 146 4-θ19 165 38 127 4-θ19 104 118 70X50DH(R)-C 216 76 178 4-θ19 184 51 146 4-θ19 191 154 70X50DHH-D 216 76 178 8-θ19 203 51 165 4-θ19 750 ---- 100X75DH(R)-C 279 102 235 4-θ22 229 76 191 4-θ22 263 236 100X75DHH-E 254 102 210 8-θ19 254 76 210 8-θ19 1250 ---- 150X100DH(R)-D 337 152 292 4-θ22 279 102 235 4-θ22 626 454 150X100DH(E)-E 337 152 292 4-θ22 279 102 235 4-θ22 728 635 150X100DHH-S 337 152 292 8-θ22 205 120 260 8-θ22 2880 ---- 200X150DH(R)-E 406 203 356 8-θ22 268 152 321 8-θ21 1473 982 200X150DH(R)-R 406 203 356 8-θ22 368 152 321 8-θ22 1655 ---- 200X150DHH-T 432 203 375 8-θ29 432 152 375 8-θ29 6586 ---- 250X200DH(R)-E 502 254 445 8-θ29 432 203 375 8-θ29 1625 1202 250X200DH(R)-R 502 254 445 8-θ29 432 203 375 8-θ29 1836 ---- 250X200DH(R)-ST 502 254 445 8-θ29 432 203 375 8-θ29 3750 3130 300X250DH(R)-ST 527 305 470 12-θ25 527 254 470 12-θ25 4318 3357 350X300DH(R)-ST 585 356 521 12-θ25 552 305 495 12-θ25 6409 4672 400X350DH-ST 705 406 341 12-θ35 673 356 610 12-θ29 10000 ---- 500X400DH-TU 900 508 800 12-θ42 900 460 800 12-θ42 18864 15921

Keywords:

Slurry Pump

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!