Contact Us

E-mail :

info@delinco.com, sales@delinco.com

WhatsApp:

+86-13930129172

Address:

271 Yuanshi Street, Shijiazhuang City, Hebei Province, China

DF(DHF) Series Slurry Pump

According to the structural form, it can be divided into two types: vertical and horizontal structures, all of which adopt a double pump casing structure.

Capacity: 1.2-186m³/h

Head: 5-30.2m

Speed (r/min):350-1800r/min

- Commodity name: DF(DHF) Series Slurry Pump

- Description

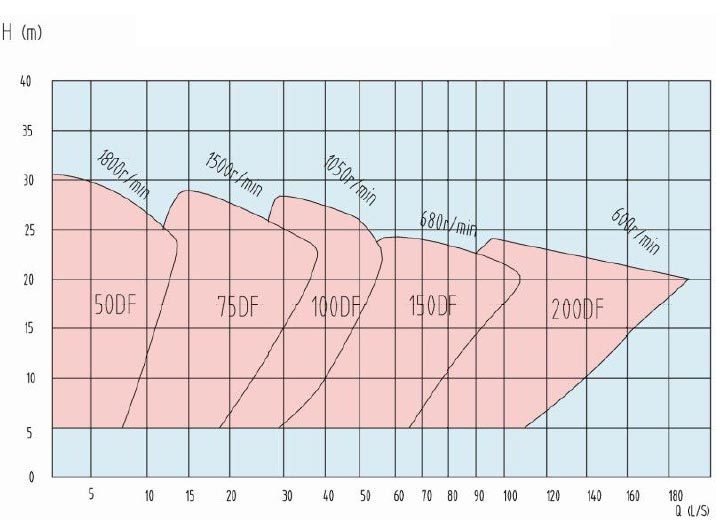

- Selection Chart

- Performance Parameter

- Installation Dimension

-

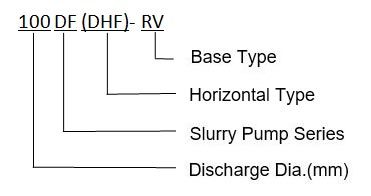

Model Meaning

Characteristic

Capacity: 1.2-186m³/h Head: 5-30.2m Speed (r/min): 350-1800r/min NPSHr(m) - Allowable Matting Max.Power(kW): 35-72kw Material: M/RU According to the structural form, it can be divided into two types: vertical and horizontal structures, all of which adopt a double pump casing structure. Efficient, wear-resistant, stable performance, and strong interchangeability of parts. The lining and impeller materials can be made of wear-resistant metal or rubber; The vertical structure does not require sealing, and the material box can be lined with rubber; The horizontal structure has a small installation space and can transport slurry with larger flow rate and higher head. The transmission method can be direct or belt transmission. The rotation direction of the pump is clockwise when viewed from the drive end.

Application

It is used in the flotation process and is the Ideal type pump for conveying foam like slurry.

A cement slurry pump is a specialized type of positive displacement pump engineered to transfer cement slurries during well construction and completion operations in the oil and gas industry. These pumps are designed to handle the high pressures and abrasive nature of cementitious mixtures, ensuring a uniform and consistent flow rate for effective well cementing.

-

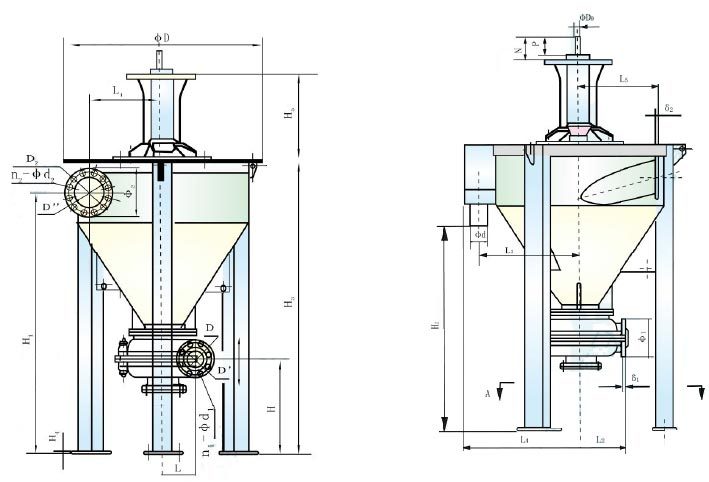

Section Chart of DF(DHF) Type Slurry Pump

-

Type Capacity(Q) Head(H) Speed(n) Max. Efficiency Max. Particle Size Allowed Allowable Mating Max. Power (m³/h) (l/s) (m) (r/min) (%) (mm) (kW) 50DF 4.3~51 1.2~14.2 6.2~30.2 800~1800 20~45 35 15 75DF 10.8~149.4 3~41.5 6.5~29.5 700~1500 20~55 38 20 100DF 10.8~212 3~59 6.8~29.2 500~1050 20~55 55 40 150DF 36~425 10~118 6.8~25.2 350~680 20~55 63 75 200DF 230~670 64~186 5~24.8 350~680 20~55 72 75 -

Type Outline Dimension H H1 H2 H3 H4 H5 L L1 L2 L3 L4 φD N P 50DF 382 1140 850 1300 12 474 138 360 210 480 380 938 174 110 75DF 467 1250 950 1400 12 474 149 354 262 510 445 938 174 110 100DF 506 1720 1310 1910 16 637 229 537 338 740 600 1444 238 170 150 DF 791 2430 1950 2770 20 875 318 696 460 1020 800 1970 300 210 200 DF 791 2430 1950 2770 20 875 381 696 470 1020 800 1970 300 210 Type Outlet Flange Dimension Inlet Flange Dimension D1 D' Φ1 n1 Φd1 δ1 D2 D'' Φ2 n2 Φd2 δ2 50DF 51 146 184 4 19 25 102 178 216 4 19 12 75DF 76 191 229 4 22 27 152 235 279 8 18 16 100DF 102 235 279 4 22 32 203 292 337 8 19 12 150DF 152 324 365 8 21 38 305 406 457 12 22 20 200DF 203 375 432 8 29 44 305 406 457 12 22 20

Keywords:

Slurry Pump

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!