Contact Us

E-mail :

info@delinco.com, sales@delinco.com

WhatsApp:

+86-13930129172

Address:

271 Yuanshi Street, Shijiazhuang City, Hebei Province, China

DG Series Gravel Pump

This series of pumps is a single stage single suction cantilever horizontal structure, and the structure of the dredging pump can be divided into two types based on the size of the discharge pressure

Capacity: 10-1000m³/h

Head:3.5-72m

Speed (r/min): 300-1400r/min

- Commodity name: DG Series Gravel Pump

- Description

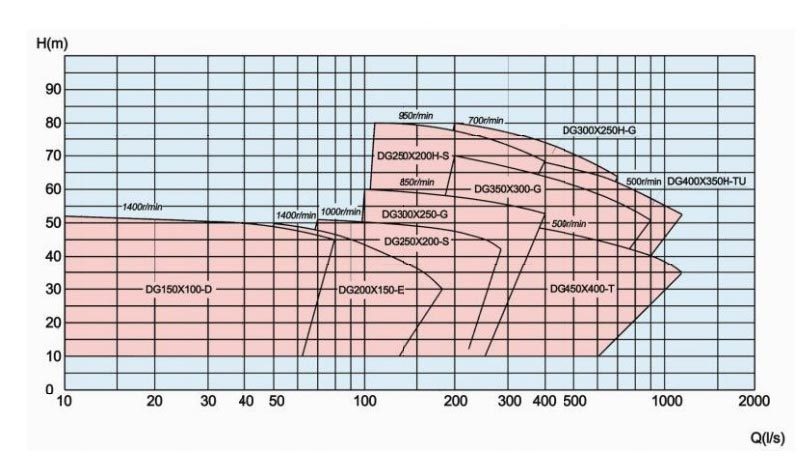

- Selection Chart

- Performance Parameter

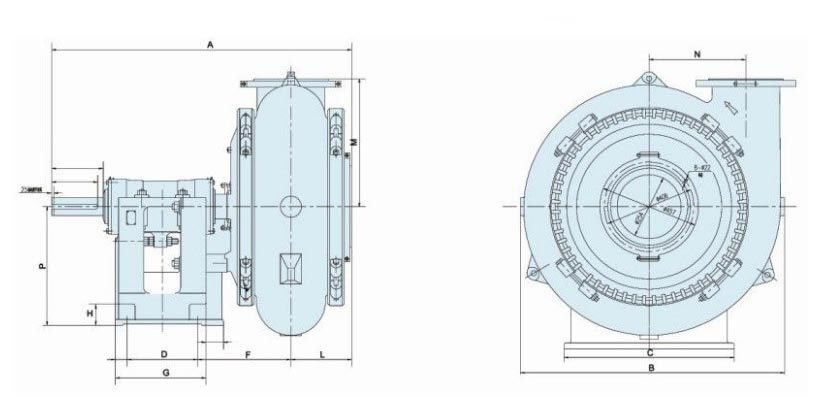

- Installation Dimension

-

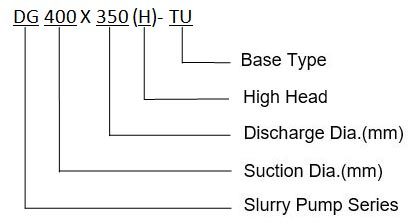

Model Meaning

Characteristic

Capacity: 10-1000m³/h Head: 3.5-72m Speed (r/min): 300-1400r/min NPSHr(m) 2.5-6m Allowable Matting Max.Power(kW): 82-254kw Material: M This series of pumps is a single stage single suction cantilever horizontal structure, and the structure of the dredging pump can be divided into two types based on the size of the discharge pressure: single pump casing and double pump casing; According to the transmission mode, it can be divided into two typical structures: the built-in bracket type and the pump box combination type (i.e. the gearbox and pump are integrated). There are two lubrication methods for the built-in bracket: grease lubrication or thin oil lubrication.

Application

River dredging, reservoir dredging, coastal reclamation, Deep sea mining, etc

The submersible slurry pump is a versatile and powerful device designed to handle abrasive and corrosive slurries in underwater environments. It is specifically engineered to be submerged in fluid, allowing for efficient pumping without the need for priming or the use of external support systems. With its compact and robust design, it can operate in deep waters and harsh conditions with ease. Equipped with high-performance impellers and wear-resistant materials, the submersible slurry pump is capable of handling solid-laden fluids with high efficiency and reliability.

Introducing the Slurry Pump, an innovative solution designed to provide efficient and reliable transport of slurries, mixtures, and other abrasive or corrosive fluids. Our product stands out for its unique design that combines advanced engineering with durable materials, ensuring optimal performance and longevity in various industrial applications.

Key Features and Advantages:

High-Performance Design: Our pumps are engineered to deliver high flow rates and pressures, ensuring efficient slurry transport even in challenging conditions. The advanced design ensures minimal maintenance requirements and low energy consumption, making it a cost-effective solution for your pumping needs.

Superior Materials: We use only the highest quality materials, such as wear-resistant alloys and corrosion-resistant coatings, to ensure exceptional durability and longevity. This makes our slurry pumps ideal for handling abrasive, corrosive, or viscous fluids in various industries.

Customizable Options: We offer a wide range of customizable options to suit your specific needs and requirements. Whether you need a small-capacity pump for laboratory applications or a large-capacity pump for mining operations, we have you covered.

Gravel Pump, a cutting-edge pumping technology designed to efficiently handle aggregate materials, has revolutionized the way industries transport gravel, sand, and other particulate substances. This innovative pump is engineered to provide exceptional performance, durability, and versatility in various applications.

Industries Served:

Gravel Pump serves multiple industries, including construction, mining, dredging, and environmental management. It plays a crucial role in projects that require the transfer of large volumes of aggregates, such as dam construction, land reclamation, and pipeline installation.Application Scenarios:

Gravel Pump is ideally suited for challenging environments and complex scenarios. Its robust design enables it to handle solid particles ranging from fine sand to large gravel, making it an essential tool for civil engineering projects, mining operations, and water management systems. -

Section Chart of DG Type Gravel Pump

-

Type Capacity(Q) Head(H) Speed(n) Max. Eff. NPSH Suction Dia. Discharge Dia. Max. Particle Size Allowed Weight (m³/h) (l/s) (m) (r/min) (%) (m) (mm) (mm) (mm) (kg) DG150X100-D 36~252 10~70 3.5~51 600~1400 30~50 2.5~3.5 150 100 82 460 DG200X150-E 137~576 38~160 10~48 800~1400 50~60 3~4.5 200 150 127 1120 DG250X200-S 216~979 60~272 13~50 500~1000 45~65 3~7.5 250 200 178 2285 DG300X250-G 360~1512 100~420 11~58 400~850 50~70 2~4.5 300 250 220 4450 DG350X300-G 504~3168 140~880 6~66 300~700 60~68 2~8 350 300 240 5400 DG450X400-T 864~3816 240~1060 9~48 250~500 60~72 3~6 450 400 254 10800 DG250X200H-S 396~1296 110~360 10~80 500~950 60~72 2~5 250 200 180 3188 DG300X400H-T 612~2232 170~620 28~78 350~700 60~72 2~8 300 250 210 4638 DG400X350H-TU 720~3600 200~1000 20~72 300~500 60~72 3~6 400 350 230 12250 -

Modal Outline Dimension A B C D E F G D1 E1 G1 H Y I N-d L M N DG150X100-D 1006 492 432 213 38 75 289 - - - 54 164 65 4-Ф22 330 203 260 DG200X150-E 1286 622 546 257 54 83 365 - - - 75 222 80 4-Ф29 392 295 352 DG250X200-S 1720 920 760 - - - - 640 70 780 90 280 120 4-Ф35 378 330 416 DG300X250-G 2010 1207 851 - - - - 749 64 876 152 356 140 4-Ф41 473 368 522 DG350X300-G 2096 1207 851 - - - - 749 64 876 152 356 140 4-Ф41 502 424 610 DG450X400-T 2320 1150 900 - - - - 880 80 1040 125 350 150 4-Ф48 538 439 692 DG250X200H-S 1774 920 760 - - - - 640 70 780 90 280 120 4-Ф35 455 330 475 DG300X400H-T 2062 1219 851 - - - - 749 64 876 152 356 140 4-Ф41 496 400 605 DG400X350H-TU 2367 1460 1200 - - - - 860 95 1050 150 350 150 4-Ф70 649 448 765 Modal Outline Dimension Intake Flange Dimension Outlet Flange Dimension Weight P Q R S T U V W D0 D2 n-d1 n0 n2 n-d2 DG150X100-D 330 343 33 32 16 - 8 5 305 260 8-Ф19 254 210 4-Ф19 460 DG200X150-E 457 405 29 29 54 - 6 8 368 324 8-Ф19 305 260 8-Ф19 1120 DG250X200-S 450 533 48 41 - 102 8 6 457 406 8-Ф22 368 324 8-Ф19 2285 DG300X250-G 851 665 48 49 238 - 10 8 527 470 12-Ф22 457 406 8-Ф22 4450 DG350X300-G 851 787 48 48 121 - 8 10 552 495 8-Ф22 527 470 12-Ф22 5400 DG450X400-T 650 921 64 64 - 274 8 10 705 641 16-Ф25 640 584 12-Ф25 10800 DG250X200H-S 450 620 48 42 - 206 8 6 457 406 8-Ф22 368 324 8-Ф19 3188 DG300X400H-T 851 800 60 60 40 - 10 8 533 476 8-Ф29 483 432 8-Ф25 4638 DG400X350H-TU 900 1008 72 82 - 120 8 10 650 600 12-Ф28 600 540 12-Ф28 12247

Keywords:

Gravel Pump

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!